You’ve probably heard the term “terroir,” especially if you like to drink wine. But, while many whiskey distilleries like to talk about the terroir of their products, there’s actually quite a big debate around whether whiskey has terroir or not. Let’s dig into that debate, but, first, let’s talk about what terroir actually means.

The concept of terroir originated in France, and it’s the idea that the climate, soil, and landscape of a region imbue crops grown there with a unique flavor character, specific to that location. Generally, this concept is mostly linked to alcoholic beverages made from grapes, such as wine or brandy, but in France it’s also applied to dairy products, such as milk and cheese, single malt, and tea and coffee. Terroir is so specific to an area, that Cognac brandy, which is only produced in the Cognac region of France following a very specifically defined process anyway, is subdivided into six classifications based on specific locales. (Interestingly, in the case of Cognac, the highest value Cognac comes from the locales with the highest amount of limestone in the soil.)

In terms of the debate around whiskey, some pundits posit that distillation removes whatever terroir the beer or wine might have had. But that argument is the easiest to dismiss in our opinion, since brandy and single malt are both distilled products. If the French think those still have terroir, who’s to argue?

There are five main factors that DO influence the flavor of whiskey: the water it’s made with, the grain recipe (a.k.a. the mash bill), fermentation (which includes the yeast that drives that fermentation), distillation, and – if it’s an aged product, such as bourbon – maturing the spirit in oak.

Those who doubt whiskey has terroir often point out that most distilleries use treated municipal water for their products. That includes such giants as Brown-Foreman, which produces Old Forester and Woodford Reserve. In response, the other side’s counterargument is that there are many distilleries in Kentucky, Tennessee, and elsewhere that do use local limestone springwater to make their products. Limestone water has a high PH, which improves fermentation, but it also needs to be low in iron for good flavor. So, whichever side you agree with on this point really depends on how much you, as a drinker, think water influences the flavor of a spirit. (Full disclosure. We at Engineered Spirits happen to think it’s very important, which is why we plan to supply our tasting room with plenty of the farm’s springwater.)

Those who disagree that whiskey can have terroir will also point out that the majority of distilleries source their grain in bulk and because of that have no knowledge of the terroir of the place where the grain was grown. That’s a great point and we agree with it. But we also know of a number of craft distilleries – not just in Tennessee, but also in other states – who are sourcing locally-grown grains, or even growing them themselves, as we are.

A second argument goes something like this. “But, No. 2 yellow corn can be grown anywhere and tastes the same no matter where it’s grown, that’s the whole point. And everyone buys their seed from the same suppliers.” That is another fair point and it’s why we think growing heirloom Jimmy Red dent corn on the farm is supremely important to the flavor of the whiskey we are producing. We’re keeping our supply chain as local as possible. That doesn’t make us unique, but it does put us in the company of a very short list of like-minded craft distilleries.

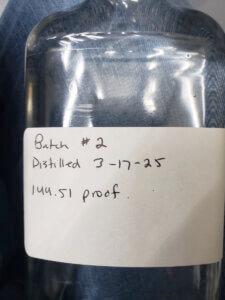

The strain of yeast used in fermentation can make a difference in the flavor of whiskey, too, and, if it’s a local “wild yeast” that would definitely support the existence of terroir in whiskey. Like most distilleries, we currently buy yeast for the products we’re experimenting with, but we have collected wild strains of yeast from the farm in the past so we could have them tested by a lab for analysis. One day, we hope to find a viable local strain that we can use exclusively in our products. But for now, we’ll have to keep working on that one.

The equipment you use and your distillation process definitely does influence the flavor of whiskey, just like the mash bill does. But the equipment and process can scarcely be tied to a specific location, nor the concept of terroir.

That brings us to the final – and arguably most important component of the whiskey-making process: aging the spirit in wood to enhance its flavor and color. For bourbon, that wood is a new, white oak barrel and the spirit must remain in that barrel for four years. Most distilleries source their barrels from one of a number of cooperages, but we’ve done things a little differently, which you’ll know if you’ve been following our blog. We sent white oak harvested here on the farm to a stave company in Kentucky almost three years ago. From there it will soon go to a nearby cooperage to be made into barrels for our products. As far as we know, we’re the only craft distillery who will be able to point to one of our barrels and say, “That barrel was grown right here.”

But, of course, more important than the wood itself for whiskey is the climate it’s aged in. The temperature variations across the seasons and the weather itself are what draw the spirit in and out of the wood. We’ll be barreling our products here and aging them in the farm’s repurposed trench silo. Seeing how our whiskey will mature in that structure is something we’re really looking forward to learning. In theory, since it’s partially underground, the barrels should stay warmer in winter and cooler in summer, allowing us to age our spirits longer. But, really, we have no idea until we do it. So, that’s exciting.

Our corn, our water, our wood. I guess we should add to that list “our weather,” and hopefully, eventually, “our yeast.” That’s our goal. “100% our whiskey.” Other craft distilleries that we admire are actively addressing some or several of these things, but we don’t know of anyone else who is actively addressing all of the elements required to achieve true terroir in a whiskey. (Although there may well be; there are a lot of craft distilleries out there.) Still, we think we’ve got a solid chance at achieving it right here on the farm.

But what do you think? Does whiskey have terroir? And what do you think is the most important factor in producing that?

Let us know in the comments.